16+ ranked positional weight calculator

The ranked positional weight computes the sum of the task and all tasks that follow. 10 marks Table 2 Operation Time min Immediate predecessor A 5 B لیا C 10 A B D 13 E 19 с F 24 D G 22 E H 16 G.

![]()

Best 10 Apps For Calculators Converters Last Updated November 1 2022

The task with the largest weight is scheduled first if it will fit in the.

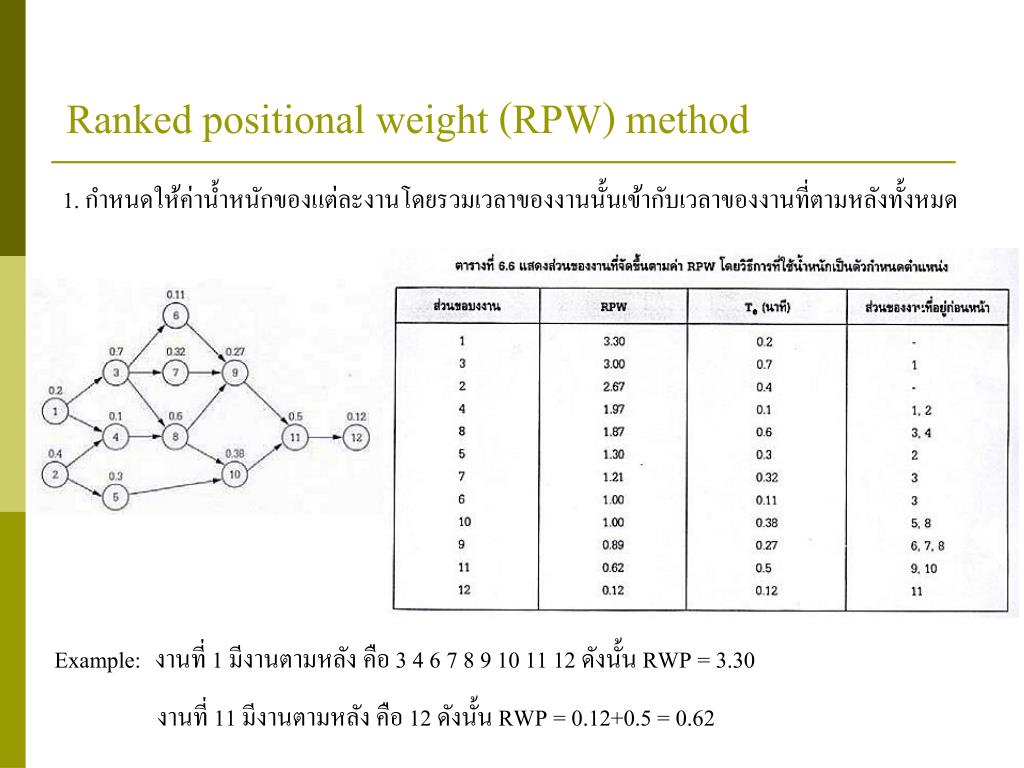

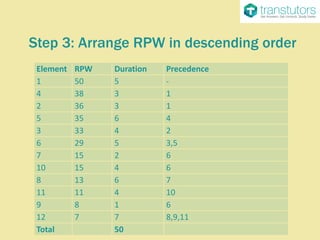

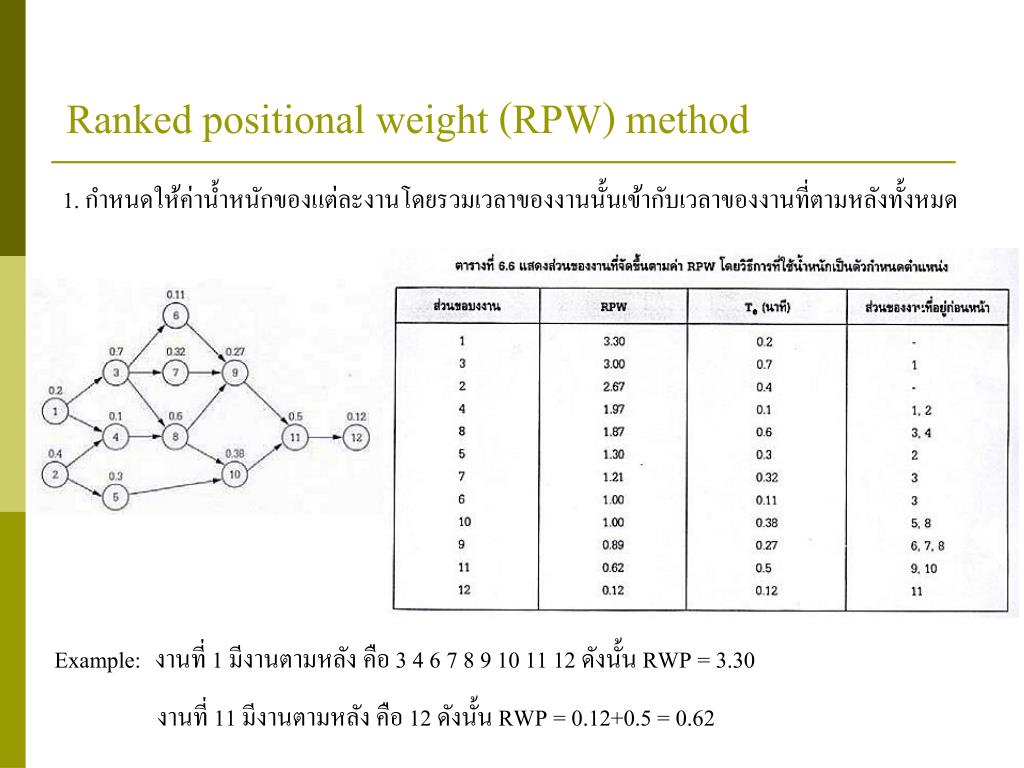

. Ranked positional weight method The ranked positional weight computes the sum of the task and all tasks that follow. Calculate RPW which is summing the work time for the element with all work time of other elements the follow it in the row of precedence. For example for task a the ranked positional weight is 1 2 7 8 18 while for task.

For example for task a the ranked positional weight is 1 2 7 8 18 while for task b the weight is 5 3 8 16. 524 Ranked Positional Weight Method 70 53 The Best Method 71 6. It is the total time on the longest path from the beginning of operation to the last operation of the network.

Short form to Abbreviate Ranked Positional Weight. For example for task a the ranked positional. 1 popular form of Abbreviation for Ranked Positional Weight updated in 2022.

This content was downloaded from IP address 15846214225 on 03062020 at 1816. Calculate line and station efficiencies. From the results obtained Longest Operating Time Technique has higher line efficiency 8516 as compared to Ranked positional weight technique 7928 and it is easy to apply.

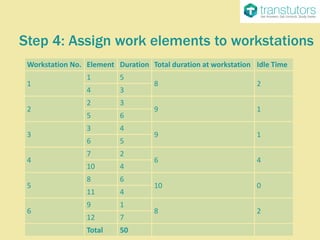

SUMMARY AND CONCLUSION 72 61 Conclusion 72 62 Recommendations for Future Work 73. The cycle time for meeting the demand is 38 minutes. Based on the data processing by the ranked positional weight method gained the.

A Balance the assembly line using the ranked positional weight method. B Assume the times are normally distributed with a mean equal to the. From the results obtained Longest Operating Time Technique has higher line efficiency 8516 as compared to Ranked positional weight technique 7928 and it is easy to apply.

The Rank Positional Weight Method can be used to develop and balance an assembly line. The ranked positional weight computes the sum of the task and all tasks that follow. For each work element determine the positional weight.

How can I increase my positional weight. For example for task a the ranked positional weight is 1 2 7 8. Ranked Positional Weights Method RPW Step 1.

In this method work elements are divided among workstations depending on. Need abbreviation of Ranked Positional Weight.

Positional Weights Of Tasks For The 14 Heuristic Rules Download Table

Ranked Positional Weight Method Management

Ranked Positional Weight Method Management

Ppt Chapter 6 Powerpoint Presentation Free Download Id 5751164

Employment And Social Developments In Europe

Implementation Of Ranked Positional Weight Method Rpwm For Double Sided Assembly Line Balancing Problems Aip Conference Proceedings Vol 1885 No 1

Manual Assembly Lines Chapter 4 Sections Ppt Video Online Download

Evaluation Of The Institute Of Nutrition Metabolism And Diabetes Research Inmd Cihr

Surface Induced Dissociation Mass Spectrometry As A Structural Biology Tool Chemical Reviews

What Math Tricks Are Hidden In Chess Quora

Ranked Positional Weight For Line Balancing Manual Assembly Line Balancing Industrial Automation Youtube

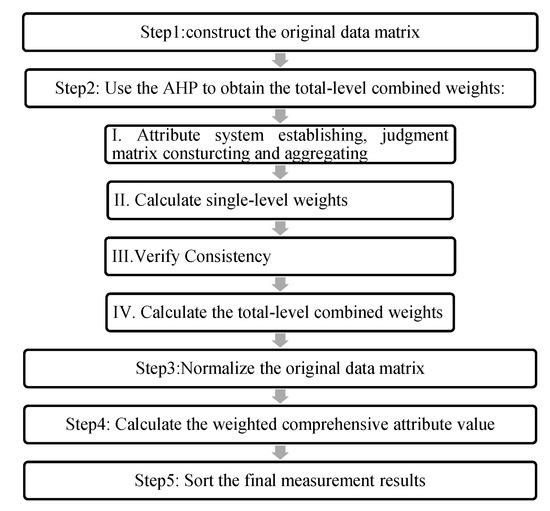

Axioms Free Full Text Study On Comprehensive Evaluation Based On Ahp Madm Model For Patent Value Of Balanced Vehicle Html

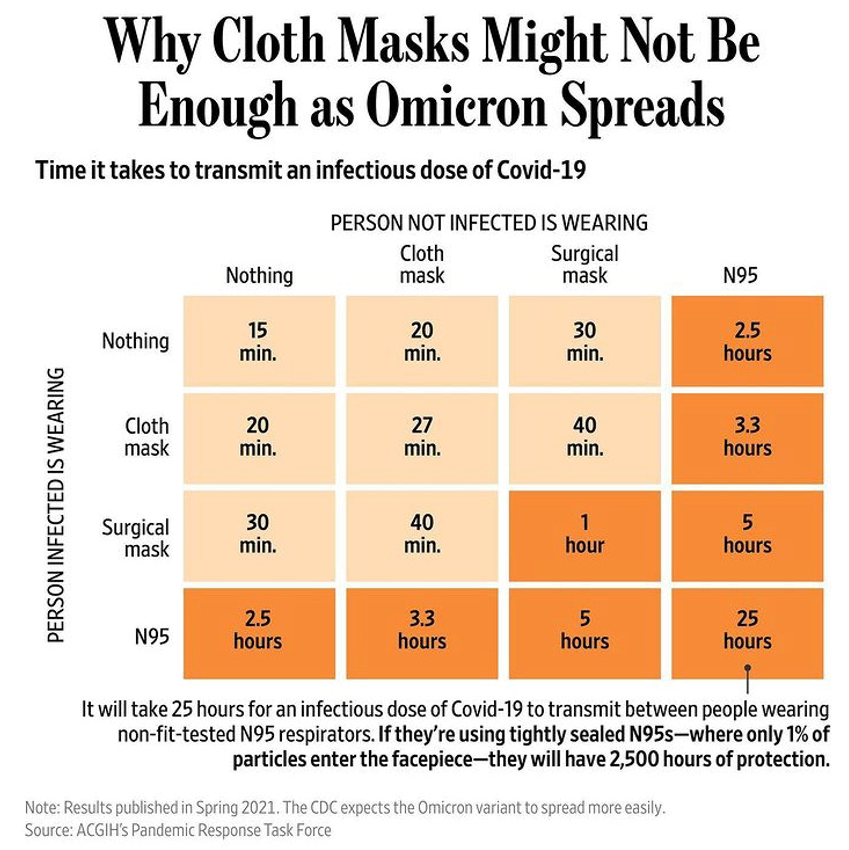

Latest Health Updates Student Health Services At Pcc Student Health Services Pasadena City College

6 5 Methods Of Line Balancing Cuiksuiqbad Rekadayaupaya

Ntse 2020 21 Stage 2 Question Paper With Solutions Pdf Download

Carer Social Care Related Quality Of Life Outcomes Estimating English Preference Weights For The Adult Social Care Outcomes Toolkit For Carers Value In Health

Axioms Free Full Text Study On Comprehensive Evaluation Based On Ahp Madm Model For Patent Value Of Balanced Vehicle Html